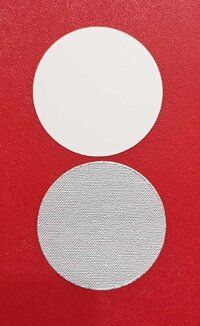

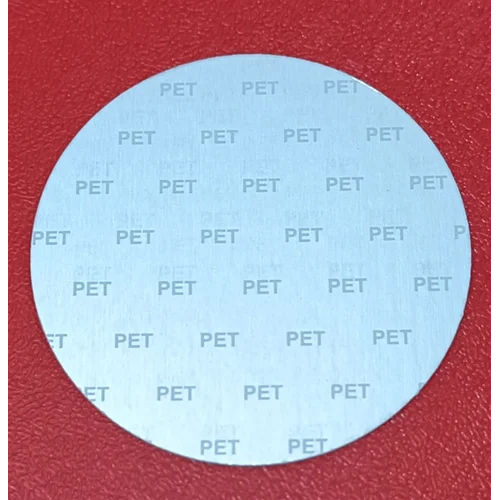

Vented Induction Sealing Wad

Product Details:

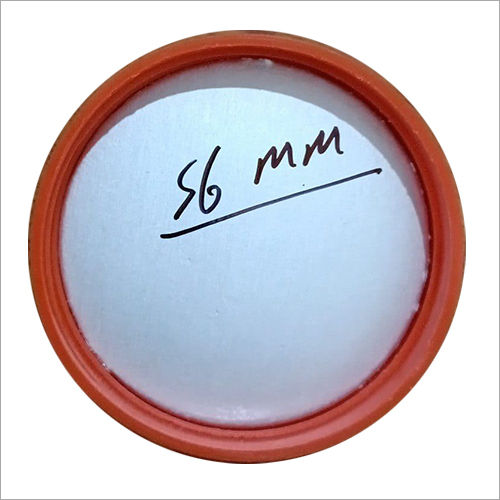

- Product Type Sealing Tapes

- Adhesive Rubber

- Color White

- Click to View more

Vented Induction Sealing Wad Price And Quantity

- 5.45 INR/Piece

- 20 Piece

Vented Induction Sealing Wad Product Specifications

- Rubber

- Sealing Tapes

- White

Vented Induction Sealing Wad Trade Information

- Cash in Advance (CID)

- 600 Piece Per Week

- 7 Days

- All India

Product Description

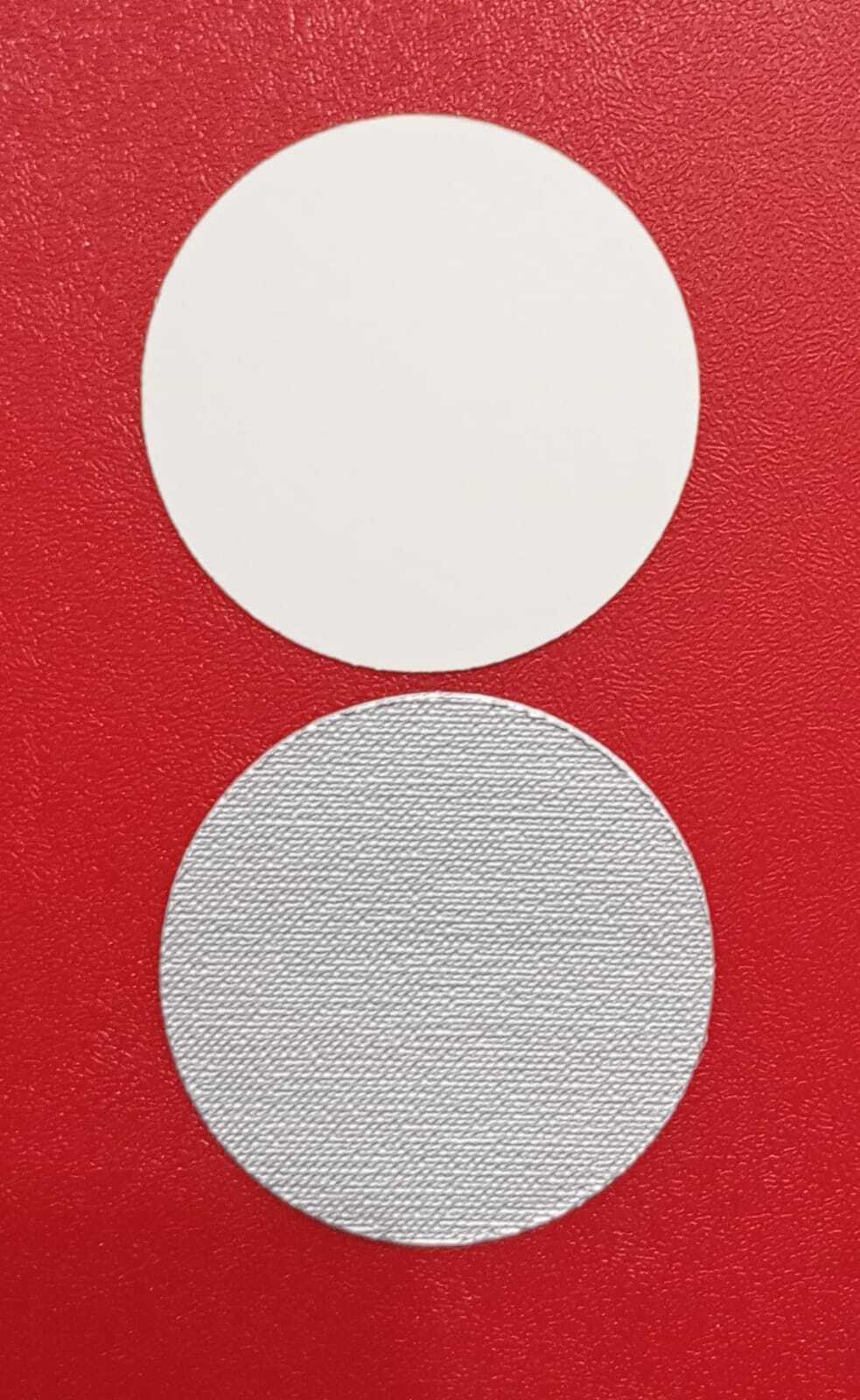

Vented Induction Sealing Wad is a much better option than any other cap sealing process as it is a reliable sealing technique subject to the optimized machine setting and material selection. It can be tested for strength using a drop test which would ensure its sustainability under harsh transportation conditions. The seal applied through the induction sealing process cannot be removed intact and thus provide tamper evidence. Also, the Vented Induction Sealing Wad can include security features like holography to prevent counterfeiting and improve brand recognition. Most industrial firms demand that liquid chemical items be sealed before they are sent to prevent leakage, which stops any other hazardous chemicals from leaking on subsequent shipments.

A vented induction sealing wad, often referred to as a vented induction seal, is a type of closure used to seal containers while allowing gases to escape. This is particularly useful for products that might release gas over time, such as certain chemicals, foods, or pharmaceuticals.

Components and Functionality

1. Induction Seal The primary component that creates a hermetic seal on the container. This is typically composed of a laminated layer of aluminum foil, polymer, and other materials that melt and bond to the container's opening when exposed to electromagnetic induction.

2. Venting Mechanism This allows gas to escape without compromising the seal. The vent can be a small hole covered by a breathable membrane or a specially designed valve that opens under pressure.

Applications

- Chemical Containers Prevents pressure buildup that could lead to container deformation or rupture.

- Food Packaging Extends shelf life by preventing spoilage gases from being trapped inside.

- Pharmaceuticals Maintains product integrity and safety by allowing gas release without exposing the contents to external contaminants.

Benefits

- Pressure Regulation Prevents container deformation or rupture due to gas buildup.

- Product Integrity Maintains a strong seal to protect contents from contamination.

- Extended Shelf Life Reduces spoilage and preserves product quality over time.

Considerations

- Material Compatibility Ensures the vented induction seal is compatible with the container material.

- Seal Strength Balances the need for a strong seal with the ability to vent gases effectively.

- Regulatory Compliance Meets industry standards and regulations for safety and efficacy.

If you have any specific questions or need detailed information on a particular aspect, feel free to ask!

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Induction Sealing Wad' category

GST : 09AARHA0518E1ZI

|

AASTHA ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese